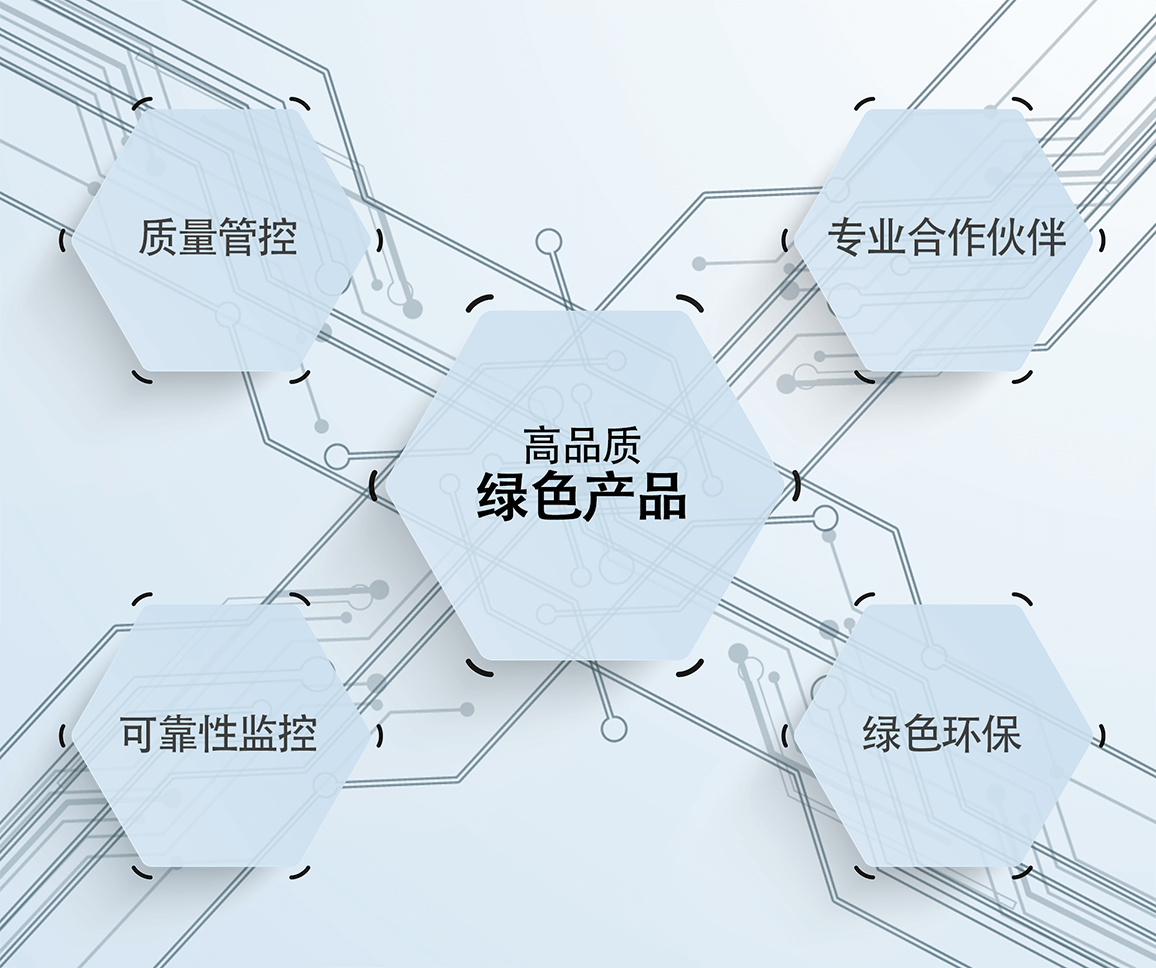

东芯质量观

Quality concept of Dosilicon

质量管控

Quality control

专业合作伙伴

Professional partners

可靠性监控

Reliability monitoring

绿色环保

Environmental protection

以优异的产品品质提升东芯在存储芯片行业中的竞争力,力争做到行业的领头者。秉承顾客至上的理念,倾听顾客需求结合自身进行持续改善,提升客户满意度,制造高品质的绿色环保产品。

Dosilicon counts on excellent product quality to enhance the competitiveness in the memory chip industry, and strives to be the leader of the industry. Adhering to the concept of customer first, we listen to customer needs to carry out constant improvement, improve customer satisfaction, and manufacture high-quality environment-friendly products.

东芯坚信不积跬步,无以至千里。只有各部门踏实的做好每一步的工作,认真负责才能制造出高品质高可靠性的绿色环保产品。因此无论是对内抑或对合作伙伴,东芯都坚持严要求,高标准。

Dosilicon firmly believes that small steps get us to faraway places. Only when all departments of the company make great efforts and be responsible can environment-friendly products of high quality and reliability be manufactured. Therefore, we Dosilicon sticks to strict requirements and high standards while dealing with both internal and cooperation partners.

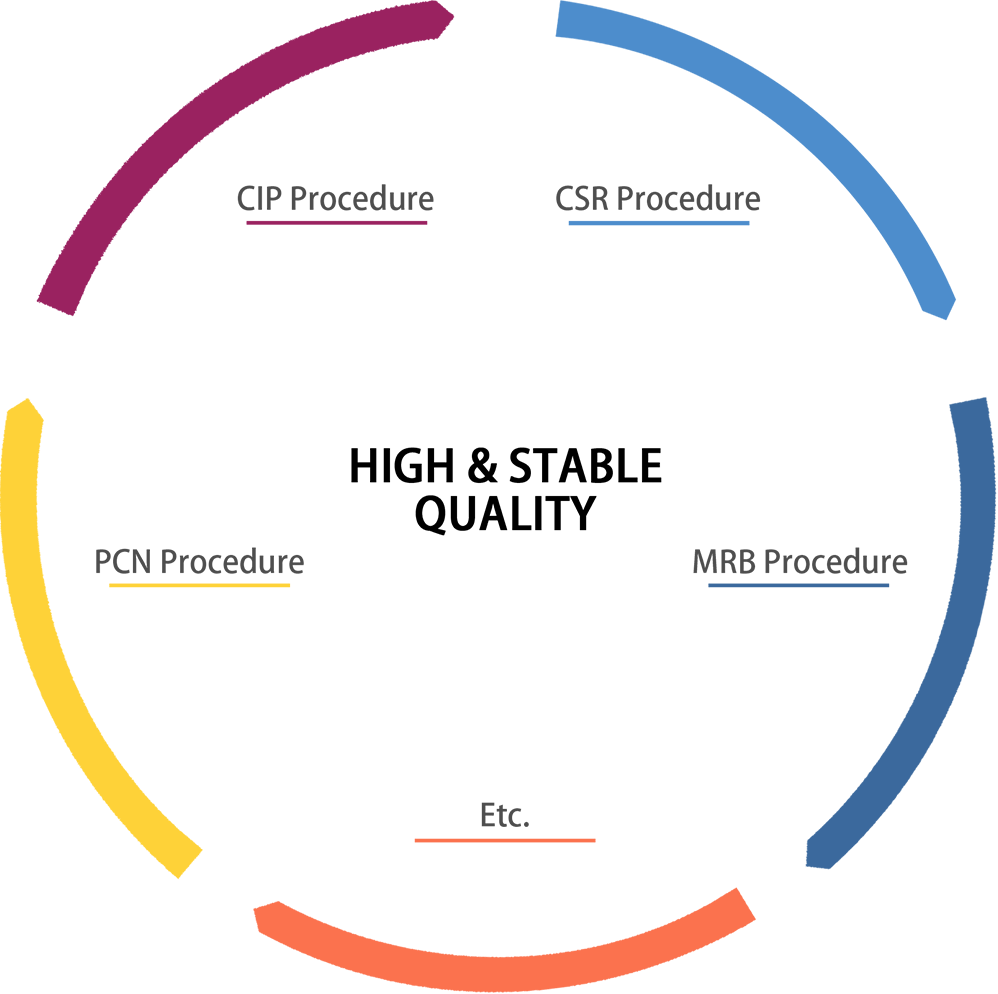

东芯秉持制造“0缺陷”,满足客户需求的高品质产品。这主要基于东芯完善的质量管理系统,其中对各个部门及工序均有标准,完整的流程。为了持续提升客户满意度,针对客户的各种需求,东芯有一套详细的评审实施流程来管理评估各个客户的各种需求。满足客户需求的同时,针对客户反馈的异常,东芯也有严格的MRB处理流程等,如果有需要东芯还能提供SEM、EDX、FIB、FTIR等先进的FA失效分析手段,可以精确定位失效模式,从而进行研究分析。在产品生产阶段,东芯有完善的SPC监控、良率监控等程序来对制程数据进行实时监控,并通过定期的评审进行持续改善。为了不影响客户对产品的使用,在产品变更过程中东芯有标准的产品变更通知流程对可能影响功能性、可靠性等方面的变更进行评估验证并通知客户。除此之外还很多其他标准的流程,机制和系统等来保障高品质产品的诞生。

Dosilicon upholds the principle of "zero defect" in manufacturing quality products to meet the customer needs. This is mainly based on the sound quality management system, which incorporates standardized and complete procedures for each department and process. Aiming at continuously improving customer satisfaction, Dosilicon has a set of detailed review process to manage and evaluate various customer needs. While meeting the customer needs, it also has a strict MRB procedure to handle customers’ complaints. If needed, advanced FA failure analysis methods such as SEM, EDX, FIB and FTIR can be provided to accurately locate the failure mode for research and analysis. During the production, there are sound SPC monitoring, yield monitoring and other procedures to monitor the process data in real time. Continuous improvement is achieved through regular review. During the product change process, to avoid affecting customers’ use of our products, there is a standard product change notification procedure to evaluate and verify the changes that may affect the functionality and reliability, and customers will be informed. In addition, there are many other standardized procedures, mechanisms and systems supporting the production of quality products.

东芯对于合作伙伴的选择、认证、管理,有这一套完整且严格的流程和标准。

Dosilicon has a set of complete and rigorous procedures and standards for the selection, verification and management of partners.

选择的合作伙伴均是业界Top供应商,有丰富的生产制造经验,且有长期的战略合作伙伴。其还通过了ISO9001/IATF16949/ISO14001/ISO45001/ESD20.20等专业认证。

All the selected partners are Tier 1 suppliers in the industry. They have rich manufacturing experience and long-term strategic cooperative relations. They have also passed ISO9001 / IATF 16949 / ISO14001 / ISO 45001 / ESD 20.20 and other professional certifications.

高品质的产品不仅体现在质量高、环保。高可靠性也是其必不可少的重要指标。

High-quality products are not only of high quality and environmental-friendly, but also of high reliability.

质量是产品现阶段的品质评判标准,可靠性是产品长期使用过程中品质的评判标准。

High quality is the quality evaluation standard at the present stage, while reliability in the long-term use of products.

东芯在新产品设计、认证、量产阶段都会进行可靠性测试同时还会进行晶圆级可靠性测试。所有的可靠性均遵循JEDEC,AEC-Q100国际通用标准进行。

In the new product design, certification, mass production stage, Dosilicon will carry out reliability testing and the wafer level reliability testing. All the reliability tests are performed in accordance with international standards of JEDEC, AEC-Q100.

东芯半导体股份有限公司,致力于成为中国领先的存储芯片设计企业。一直将节能环保作为贯穿整个芯片设计生产的目标,同时我们针对有害物质建立管理及检查机制。从物料源头到产品生产,完全符合所有有害物质的管制要求,且生产过程所使用的各种化学品也符合标准原则。我们所生产的产品符合欧盟电机电子产品中有害物质限用指令(RoHS 2.0 (2011/65/EU)。对RoHS 2.0中限制产品使用的十种限用物质(铅Pb、汞Hg、镉Cd、六价铬Cr6+、聚溴联苯PBBs、聚溴二苯醚PBDEs、四项塑化剂邻苯二甲酸酯(DEHP、BBP、DBP、DIBP))不得超过最大浓度。并提供均质材料的第三方检测报告作为符合依据。同时我们遵守政府环保与安全卫生法令要求,详实调查供应链中的金(Au)、钽(Ta)、钨(W)、锡(Sn)、钴(Co)这类冲突金属并非来自刚果民主共和国(DRC),及其周边卢旺达(Rwanda)、乌干达(Uganda)、布隆迪(Burundi)、坦桑尼亚(Tanzania)、肯尼亚(Kenya)等冲突地区的矿区。

Dosilicon is committed to becoming China's leading memory design enterprise. Energy saving and environmental protection have always remained at the core of our vision throughout the whole chip design and production. We also have established a management and inspection mechanism for hazardous substances. From material sources to product production, we have conformed to all the control requirements of hazardous substances, and all chemicals used in the production process are also in line with the standard principles. Our products comply with the RoHS II---Restriction of the Use of Certain Hazardous Substances in Electrical and Electronic Equipment (2011 / 65 / EU). The ten substances (Pb, Hg, CD, Cr6+, PBBs, PBDEs, and the four Plasticizer phthalate including DEHP, BBP, DBP, DIBP) restricted in RoHS II will not exceed the maximum concentration. The third-party test report of homogeneous materials is provided as the proof. In addition, we comply with the requirements of the government's environmental protection and safety and health decree, and have detailed investigations on conflict metals such as Au, Ta, W, Sn and Co in the supply chain, making sure that these metals are not from conflict mining areas in the Democratic Republic of Congo (DRC) and its surrounding Rwanda, Uganda, Burundi, Tanzania, Kenya, etc.

如果您有任何疑问或需要其他信息,请与我们联系。

For any question or inquiry about other information, please

contact us.